In the manufacturing of high-performance components, titanium is unforgiving.[1][2] Unlike steel, which allows for a relatively wide processing window, the success of a titanium forging project hinges entirely on precise thermal management.

For engineers and procurement managers sourcing large titanium forgings—such as seamless rolled rings for jet engines or massive open die blocks for subsea valves—understanding the titanium forging temperature is critical. A deviation of just 50°C can result in irreversible “Alpha Case” formation or catastrophic “Beta Brittleness.”

This guide dives deep into the optimal temperature ranges for large-scale forging processes and how to manage heat during the production of Ti-6Al-4V and other critical alloys.[3]

Why Titanium Forging Temperature is Critical

Titanium alloys (most notably Ti-6Al-4V) are allotropic, meaning their crystal structure changes with temperature.[4]

- The Beta Transus: This is the specific temperature (approx. 995°C for Ti-64) where the microstructure transforms from Alpha+Beta to 100% Beta phase.

- The Risk: Forging above this temperature (Beta Forging) improves formability but can lead to coarse grains and reduced ductility.[3] Forging too far below it causes cracking.[5]

- The Challenge for Large Parts: Large forgings lose heat rapidly on the surface while retaining heat in the core. Balancing this gradient is the art of the titanium forging temperature control.

Optimal Temperature Ranges by Process

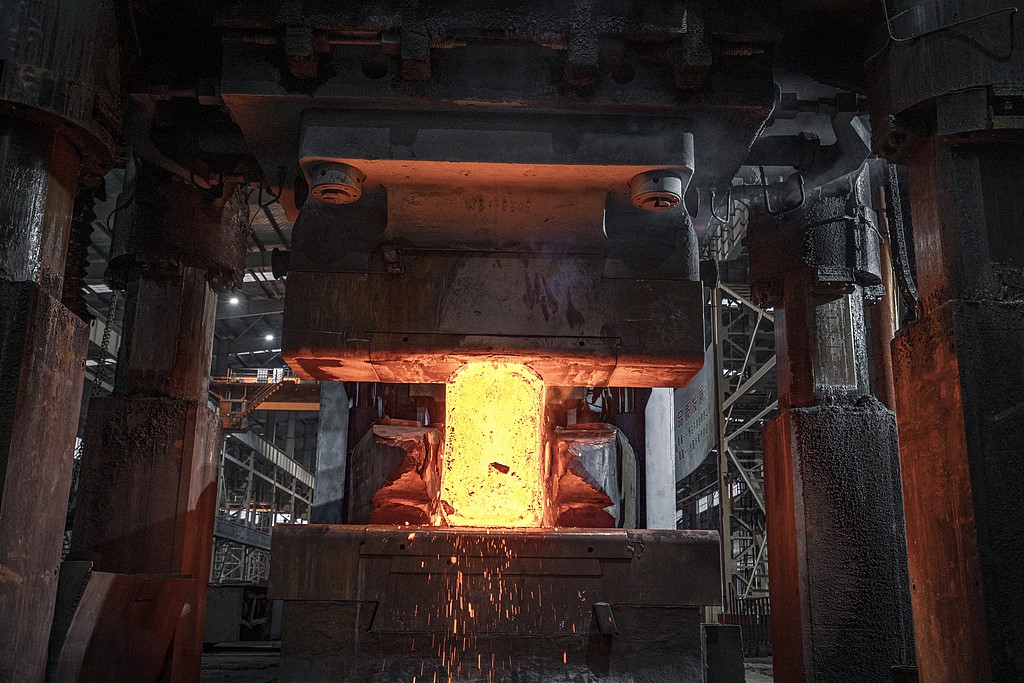

Different forging methods require different thermal strategies. Here is how we manage temperature for open die and rolled ring processes.

1. Seamless Rolled Ring Forging

Ring rolling is a continuous deformation process. The thin walls of a large ring have a high surface-to-volume ratio, leading to rapid heat loss.

- Temperature Range: Typically 900°C – 950°C (Alpha-Beta range).

- The “Adiabatic” Effect: The high-speed rolling generates internal friction heat. If the rolling speed is too high, the internal temperature can spike above the Beta Transus, ruining the grain structure.

- Solution: We use controlled rolling speeds and frequent reheats (intermediate heating) to keep the ring within the +/- 15°C safe window.

2. Open Die Forging (Large Blocks & Shafts)

For massive components like valve blocks or propeller shafts, “Soaking Time” is as important as the temperature itself.

- Pre-Heating: Large billets must be heated slowly to prevent thermal shock cracking.

- Soaking: The material must be held at the forging temperature (e.g., 940°C) long enough for the core to reach equilibrium, but not so long that grains grow excessively.

- Die Heating: To prevent “die chill” (where the cold tool sucks heat out of the workpiece), forging dies must be preheated to approx. 300°C – 400°C.

Common Alloys and Their Forging Temperatures

While exact specifications (like AMS 4928 or AMS 4965) dictate the final parameters, here are the general working ranges:

- Ti-6Al-4V (Grade 5):

- Forging Start: 930°C – 955°C (Below Beta Transus)

- Forging Finish: Must finish before dropping below 800°C to avoid cracking.

- Ti-6Al-2Sn-4Zr-2Mo (Ti-6242):

- Forging Temp: 955°C – 980°C. This high-temp alloy is stiffer and requires higher forging loads.

- Commercially Pure (CP) Titanium:

- Forging Temp: 800°C – 900°C. Easier to forge but requires clean furnace atmospheres to prevent hydrogen pickup.

The Consequence of Incorrect Temperature

What happens if the titanium forging temperature is not strictly controlled?

- Alpha Case (Surface Embrittlement): At high temperatures, titanium absorbs oxygen, forming a hard, brittle “Alpha Case” layer.[4] This layer creates micro-cracks and must be removed by expensive machining or chemical milling.

- Grain Growth: Overheating causes grains to bloom, significantly reducing the fatigue life of the part (unacceptable for aerospace).

- Flow Localization: Underheating causes the metal to flow unevenly, creating “shear bands” that act as internal weak points.

Conclusion

Mastering the titanium forging temperature is what separates a standard forge from a high-performance aerospace supplier. It requires not just the right furnaces, but the expertise to manage heat loss during the transfer from furnace to press.

We specialize in the open die and rolled ring forging of titanium alloys, ensuring compliance with AMS and ASTM standards. If you need large titanium components with verified microstructural integrity, contact our engineering team today.

Custom Open Die Forging: The Ultimate Solution for Heavy Industrial Components

In the world of heavy manufacturing, off-the-shelf components rarely meet the rigorous demands of critical…

Seamless Rolled Ring Forging: The Ultimate Guide to Heavy Industrial Rings

In sectors like wind energy, aerospace, and heavy mining, component failure is catastrophic. When engineers…

Titanium Forging Temperature Guide: Controlling Heat for Large Rings & Open Die Components

In the manufacturing of high-performance components, titanium is unforgiving.[1][2] Unlike steel, which allows for a relatively wide…

The Gear Forging Process: Manufacturing Large Rings and Heavy Duty Blanks

Introduction:In the realm of heavy industry—whether it’s the main gearbox of a wind turbine or…

The Titanium Forging Process: A Complete Guide to High-Performance Components

Introduction:In industries where failure is not an option—such as aerospace, medical implants, and subsea oil…

Open Die Forging and Closed Die Forging: What Is the Difference?

Introduction:In the metalworking industry, forging is renowned for producing components with superior strength and reliability….