Introduction:

In the metalworking industry, forging is renowned for producing components with superior strength and reliability. However, for procurement managers and engineers, a common dilemma arises during the design and sourcing phase: determining the right process. The choice between open die forging and closed die forging can significantly impact your project’s cost, lead time, and mechanical properties.

While both methods improve the grain structure of the metal, they serve very different purposes. In this comprehensive guide, we break down the mechanics, advantages, and ideal applications of both processes to help you make the best manufacturing decision.

What Is Open Die Forging?

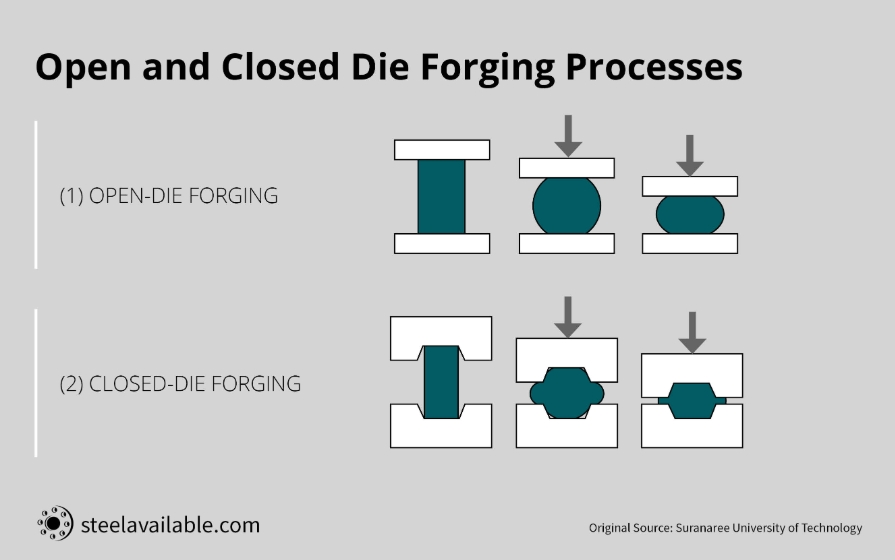

Open die forging, often referred to as “free forging” or “smith forging,” is the modern evolution of the traditional blacksmith working with a hammer and anvil. In this process, the metal is not fully enclosed by the dies. instead, flat or simple-shaped dies hammer or press the metal to shape it.

The operator (or a manipulator) rotates and positions the workpiece while a hammer or hydraulic press deforms it.

Key Characteristics:

- Tooling: Simple, inexpensive dies.

- Size: Capable of handling massive components (up to 100+ tons).

- Flexibility: Excellent for custom shapes and low-volume runs.

[Large Scale Open Die Capabilities]

What Is Closed Die Forging?

Closed die forging, also known as “impression die forging,” involves placing the hot metal into a custom-made die set that contains the negative impression of the final part. As the two halves of the die are brought together (via hammer or press), the metal is forced to fill the cavity, taking on a complex shape.

This process usually results in a small amount of excess material called “flash,” which is trimmed off later.

Key Characteristics:

- Tooling: Requires expensive, custom-machined molds.

- Precision: Produces near-net-shape parts with tight tolerances.

- Volume: Ideal for high-volume mass production.

Open Die Forging and Closed Die Forging: The Key Differences

To understand the difference between open die forging and closed die forging clearly, we must look at four critical factors: Cost, Size, Quantity, and Shape.

1. Cost Implications

- Open Die: Low tooling costs (no custom molds required). However, the unit price per piece may be higher due to slower production speeds and more machining required (higher material waste).

- Closed Die: High initial tooling investment (dies can cost thousands of dollars). However, the unit price drops significantly for large production runs due to speed and material efficiency.

2. Size and Weight Capabilities

- Open Die: This is the king of large parts. If you need a 20-ton shaft for a ship or a massive ring for a wind turbine, open die is the only option.

- Closed Die: Generally limited to smaller parts, typically under 250kg (though larger presses exist, they are rare).

3. Complexity and Precision

- Open Die: Produces simple shapes (discs, rings, shafts, blocks). It requires significant secondary machining to achieve final tolerances.

- Closed Die: Can create complex 3D geometries with intricate details. It offers excellent dimensional accuracy, reducing the need for machining.

Which Process Should You Choose?

When deciding between open die forging and closed die forging, consider the following scenarios:

Choose Open Die Forging If:

- You need a very large component (e.g., a 5-meter long shaft).

- The order quantity is small.

- You need a prototype quickly and don’t want to pay for molds.

- The part requires superior structural integrity for critical safety applications.

Choose Closed Die Forging If:

- You need thousands of identical parts (e.g., automotive gears, connecting rods).

- The part has a complex shape that would be too expensive to machine from a block.

- Material savings are a priority (precision forging reduces waste).

Conclusion

- Open Die offers flexibility and size for heavy industry.

- Closed Die offers precision and efficiency for mass production.

Seamless Rolled Ring Forging: The Ultimate Guide to Heavy Industrial Rings

In sectors like wind energy, aerospace, and heavy mining, component failure is catastrophic. When engineers…

Titanium Forging Temperature Guide: Controlling Heat for Large Rings & Open Die Components

In the manufacturing of high-performance components, titanium is unforgiving.[1][2] Unlike steel, which allows for a relatively wide…

The Gear Forging Process: Manufacturing Large Rings and Heavy Duty Blanks

Introduction:In the realm of heavy industry—whether it’s the main gearbox of a wind turbine or…

The Titanium Forging Process: A Complete Guide to High-Performance Components

Introduction:In industries where failure is not an option—such as aerospace, medical implants, and subsea oil…

Open Die Forging and Closed Die Forging: What Is the Difference?

Introduction:In the metalworking industry, forging is renowned for producing components with superior strength and reliability….

The Gear Blank Manufacturing Process: From Billet to Precision Component

Before a gear can drive a wind turbine or power a heavy excavator, it starts…