Custom Forged Gears & Gear Blanks Manufacturer

Introduction:

Are you looking for high-performance forged gears that can withstand extreme loads and harsh environments? We specialize in manufacturing custom steel gear forgings for heavy industries. From raw forged blanks to fully machined and ground gears, we deliver precision, durability, and compliance with international standards (AGMA, DIN, ISO).

Why Choose Forged Gears Over Castings?

In critical power transmission applications, failure is not an option. Forging provides superior mechanical properties compared to casting or machining from bar stock.

Continuous Grain Flow: The forging process aligns the metal’s grain structure with the contour of the gear teeth, significantly increasing fatigue strength and impact resistance.

Elimination of Defects: Forging closes internal voids and porosity, ensuring a dense, uniform structure essential for high-stress environments.

Cost Efficiency: Near-net-shape forging (precision forging) reduces material waste and machining time.

Our Gear Forging Capabilities

We offer a “One-Stop” solution, from raw material selection and die forging to heat treatment and final machining.

1. Product Range

Forged Gear Blanks: Ring rolled blanks and die-forged discs ready for machining.

Spur & Helical Gears: For large gearboxes and industrial drives.

Bevel Gears: Straight and spiral bevel gears for changing drive direction.

Planetary Gears & Sun Gears: High-precision components for epicyclic gear trains.

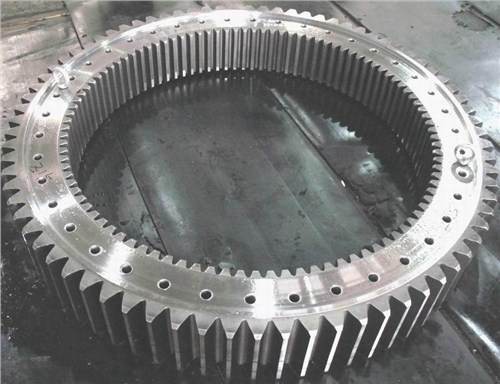

Ring Gears: Large diameter rings for kilns and excavators.

2.Material Expertise

We work with premium alloy steels to ensure optimal hardenability and wear resistance.

Carburizing Steels: 18CrNiMo7-6 (1.6587), 20CrMnTi, SAE 8620. Ideal for high surface hardness and tough cores.

Quenched & Tempered Steels: 42CrMo4 (4140), 34CrNiMo6 (4340). Perfect for high strength and toughness.

3. Precision Machining & Heat Treatment

A forged gear is only as good as its finishing.

Heat Treatment: Normalizing, Quenching & Tempering (Q&T), and Carburizing to depths of 2mm-4mm depending on requirements.

Gear Grinding: We achieve gear tooth quality of DIN Class 5-6, ensuring quiet operation and high efficiency.

Industries We Serve

Our custom forged gears are the driving force behind machinery in various sectors:

Wind Energy: Main gearbox components and yaw drives.

Mining & Construction: Excavator slewing rings, crusher drives, and conveyor systems.

Oil & Gas: Mud pump gears and drilling rig components.

Marine: Propulsion gearbox gearing.

Quality Control & Inspection

Every gear leaving our facility undergoes rigorous testing to ensure it meets your specifications.

Dimensional Inspection: CMM testing for tooth profile and lead.

Non-Destructive Testing (NDT): UT (Ultrasonic) and MT (Magnetic Particle) testing to detect surface and sub-surface cracks.

Hardness Testing: Verification of case depth and core hardness.

Get a Quote for Your Project

Ready to source high-quality forged gears directly from the manufacturer? Send us your drawings or specifications today. Our engineering team will provide a competitive quote and technical support within 24 hours.

If you need it, please fill out the form below and we will contact you as soon as possible