Ring forging

We can customize various shapes of annular forgings for you

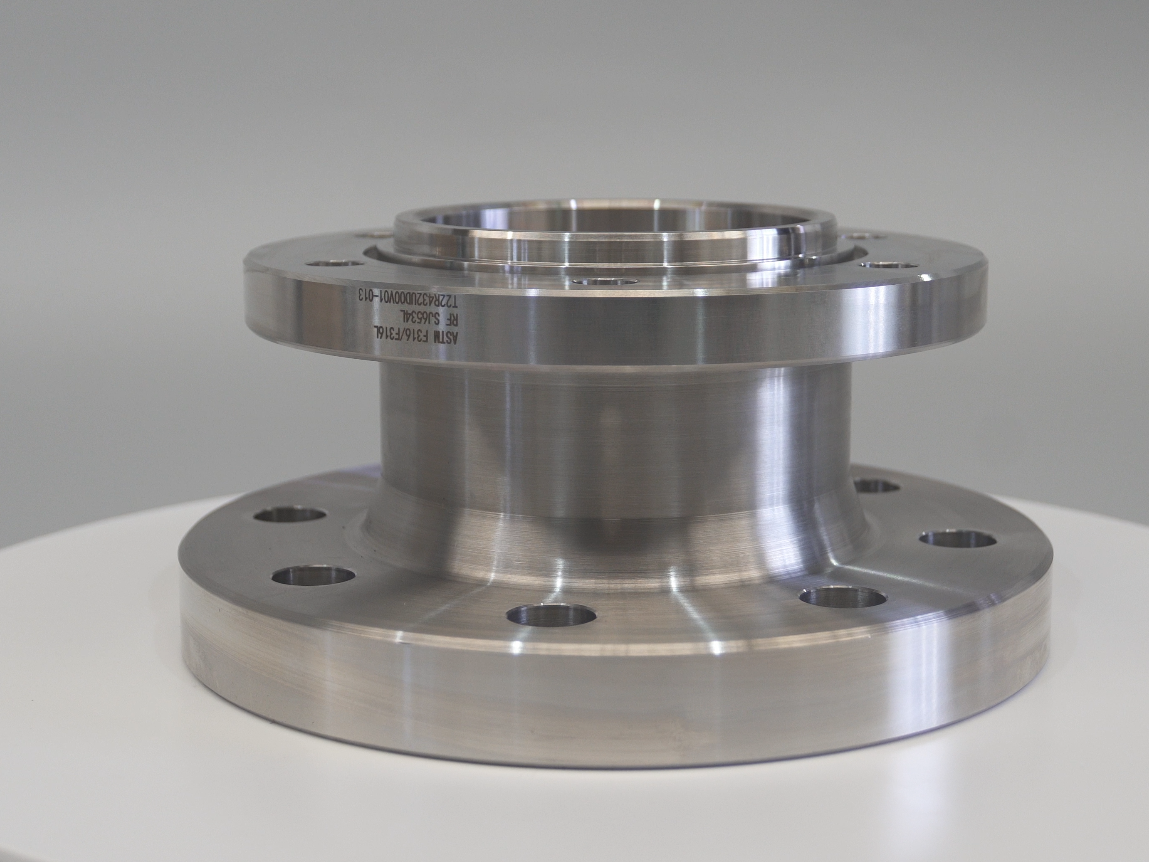

Oil & Gas Forged Flanges

Our forged flanges are widely used in oil & gas pipelines, refineries, and petrochemical plants. Manufactured from high-quality carbon steel, alloy steel, and stainless steel, each flange is designed to withstand high pressure and harsh working conditions.

Key Features:

• Sizes up to Ø 10,000 mm and weight up to 20tons

• Manufactured according to API, ASTM, ASME, DIN, EN standards

• Types available: weld neck, slip-on, blind, ring joint, socket weld

• 100% tested with UT, MT, PMI, and mechanical properties inspection

• Custom design available for critical projects

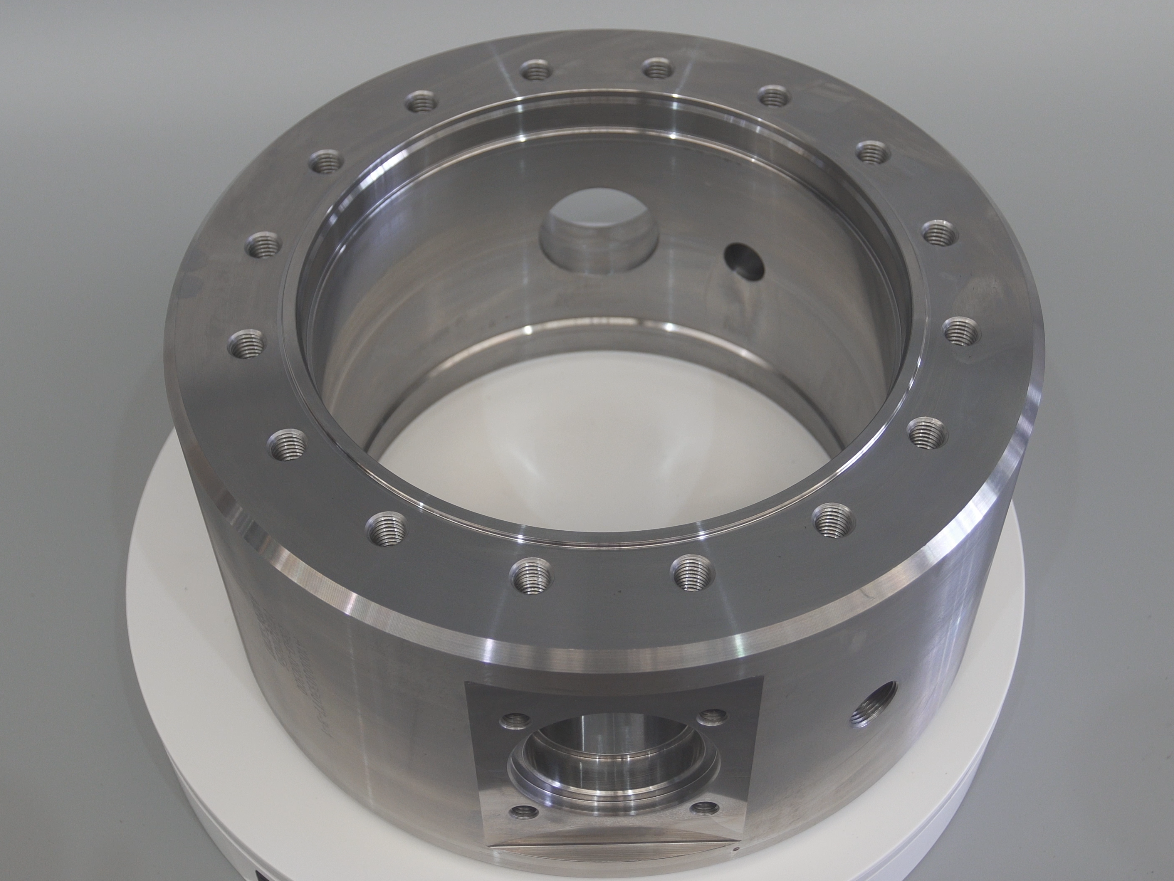

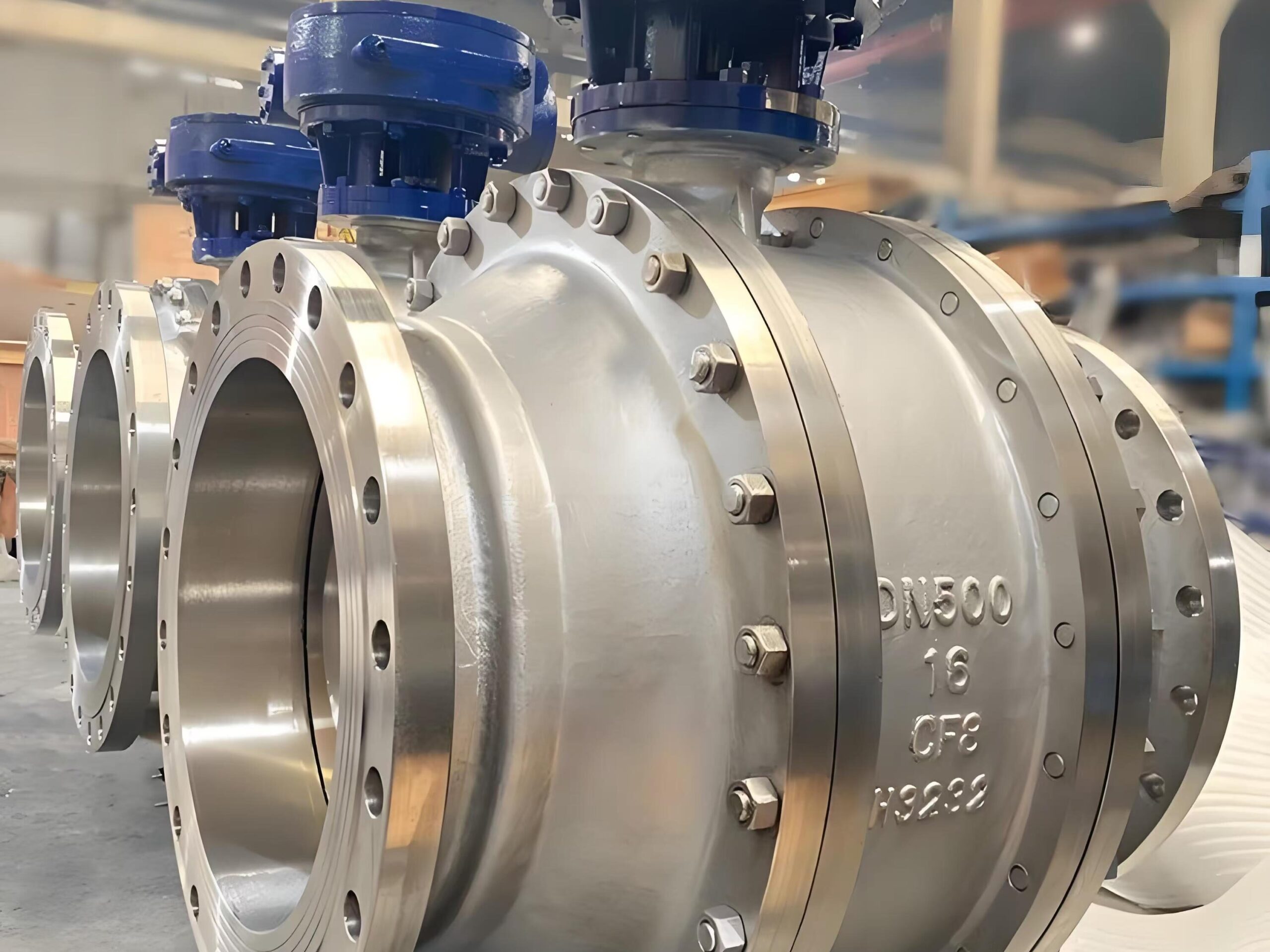

Custom Open Die Forging & Heavy Components

We specialize in manufacturing large-scale custom forgings for the toughest industrial applications. Utilizing high-tonnage hydraulic presses, we transform raw ingots into high-integrity components with superior grain flow. From marine propulsion to high-pressure vessels, we deliver precision and strength.

- Forged Shafts: Marine shafts, rotor shafts, and wind turbine spindles .

- Discs & Rings: Heavy gear blanks, tube sheets, and blind flanges.

- Blocks & Valves: Rectangular blocks and fluid control valve bodies with 100% UT testing.

Precision Forged Gears & Gear Blanks

Engineered for the most demanding environments, our custom forged gears deliver unmatched strength and fatigue resistance compared to castings. We specialize in manufacturing heavy-duty gear forgings using premium steel grades like 18CrNiMo7-6 and 42CrMo4. From rough forged blanks to fully machined, ground, and heat-treated components, we provide “One-Stop” solutions for wind energy, mining, and industrial gearboxes.

Key Features

Superior Grain Flow: Enhanced impact toughness.

Material Expertise: Carburizing & Q/T steels.

High Precision: Gear grinding to DIN Class 5/6.

Custom Sizes: Tailored to your drawings.

Titanium Forgings & Industrial Titanium Products

We supply a wide range of industrial-grade titanium materials and titanium alloy forgings, widely used in petrochemical, wind power, chemical processing, marine engineering, and pressure vessels. Our products meet international standards (ASTM / AMS / GB / ISO).

We specialize in the production and export of industrial-grade titanium forgings. With advanced forging technology and strict quality control, we deliver reliable titanium components such as rings, flanges, discs, shafts, and customized parts.

Our products are widely used in petrochemical, wind power, chemical processing, marine engineering, and pressure vessels, meeting international standards (ASTM, AMS, GB, ISO).

High strength & excellent corrosion resistance

Customized forging up to 15 tons per piece

Material certificates available: EN 10204-3.1 / 3.2

As a trusted titanium forging supplier from China, we provide high-quality solutions at competitive cost to support your global projects.

If you have any forging needs, please contact us.

Seamless Rolled Ring Forging: The Ultimate Guide to Heavy Industrial Rings

In sectors like wind energy, aerospace, and heavy mining, component failure is catastrophic. When engineers…

Titanium Forging Temperature Guide: Controlling Heat for Large Rings & Open Die Components

In the manufacturing of high-performance components, titanium is unforgiving.[1][2] Unlike steel, which allows for a relatively wide…

The Gear Forging Process: Manufacturing Large Rings and Heavy Duty Blanks

Introduction:In the realm of heavy industry—whether it’s the main gearbox of a wind turbine or…

The Titanium Forging Process: A Complete Guide to High-Performance Components

Introduction:In industries where failure is not an option—such as aerospace, medical implants, and subsea oil…

Open Die Forging and Closed Die Forging: What Is the Difference?

Introduction:In the metalworking industry, forging is renowned for producing components with superior strength and reliability….

The Gear Blank Manufacturing Process: From Billet to Precision Component

Before a gear can drive a wind turbine or power a heavy excavator, it starts…