In the realm of heavy-duty machinery and power transmission, the choice of material dictates the lifespan and reliability of the equipment. Among the various alloy steels available, 18CrNiMo7-6 (1.6587) stands out as the gold standard for manufacturing high-performance gear forgings.

Whether used in the massive gearboxes of wind turbines or the drive systems of mining excavators, this carburizing steel offers an unmatched balance of core toughness and surface hardness. This article explores why 18CrNiMo7-6 is the preferred choice for gear engineers and the critical processing points required to manufacture premium forgings.

What is 18CrNiMo7-6 Steel?

18CrNiMo7-6 is a low-carbon, case-hardening steel defined by European standard EN 10084. It is chemically similar to the older DIN grade 17CrNiMo6.

- Key Composition: It contains Chromium (Cr), Nickel (Ni), and Molybdenum (Mo).

- The “Secret Weapon”: The Nickel content adds toughness, while Molybdenum ensures deep hardenability.

- Why it matters: This chemical makeup allows the gear to have a rock-hard, wear-resistant surface (after carburizing) while maintaining a ductile, shock-absorbing core.

Why Choose 18CrNiMo7-6 for Gear Forgings?

For purchasers and designers, selecting 18CrNiMo7-6 gear forgings offers three distinct advantages over standard alloy steels like 42CrMo4.

1. Superior Fatigue Strength

Gears in heavy machinery undergo millions of load cycles. 18CrNiMo7-6 demonstrates exceptional high-cycle fatigue strength, reducing the risk of tooth breakage under continuous stress.

2. Excellent Hardenability

Large module gears (such as those used in wind power) have thick cross-sections. This material ensures that the mechanical properties are consistent from the surface down to the core, even in large-sized forgings.

3. High Impact Toughness

In applications like mining crushers, gears face sudden shock loads. The tough core structure of this steel prevents catastrophic brittle fractures.

Key Applications in Industry

Due to its premium properties, 18CrNiMo7-6 gear forgings are widely used in:

- Wind Energy: Main gearbox gears and shafts.

- Marine Engineering: Propulsion system reducers.

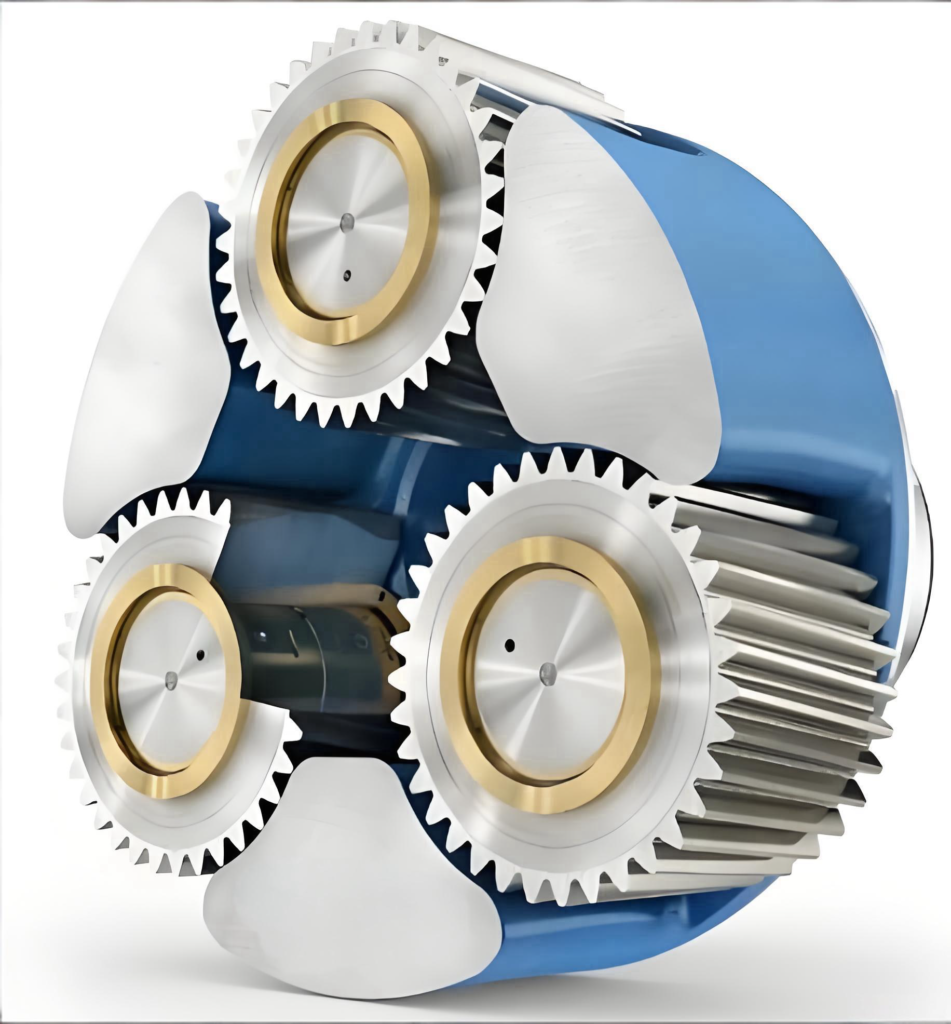

- Heavy Mining: Excavator planetary gears and crusher drives.

- Rail Transport: Locomotive traction gears.

View our portfolio of [Custom Gear Forgings]

Processing Points: From Forging to Finished Gear

Manufacturing a high-quality gear from 18CrNiMo7-6 requires strict control over the production process. Here are the critical processing points:

1. The Forging Process

- Temperature Control: Forging should typically occur between 850°C and 1150°C.

- Forging Ratio: A sufficient forging ratio (usually >3:1) is necessary to break up carbides and refine the grain structure, ensuring the “grain flow” follows the gear tooth profile.

2. Preliminary Heat Treatment (Normalizing/Annealing)

Before machining, the forged blank must undergo Isothermal Annealing. This improves machinability and reduces distortion during the final heat treatment. Without this step, the material is too gummy and difficult to cut.

3. Carburizing and Quenching

This is the most critical stage. The machined gear is heated in a carbon-rich atmosphere.

- Goal: To achieve a surface hardness of 58-62 HRC while keeping the core hardness around 32-40 HRC.

- Challenge: Controlling distortion. Expert manufacturers use press quenching or fixture quenching to minimize warping.

4. Gear Grinding

After hardening, the gear teeth are ground to precise tolerances (often DIN Class 5 or better). Since the surface is extremely hard, specialized grinding wheels are used to prevent “grinding burns” which can ruin the part.

Conclusion

18CrNiMo7-6 gear forgings represent the pinnacle of material science for heavy-duty power transmission. However, the material is only as good as the manufacturing process. From the initial forging temperature to the final carburizing depth, every step matters.

If you are sourcing reliable forged gear blanks or finished gears, you need a partner with deep metallurgical expertise. Contact our team today to discuss how we can support your project with certified 18CrNiMo7-6 components.